Scenario Planning in S&OP

Preparing for Market Uncertainties

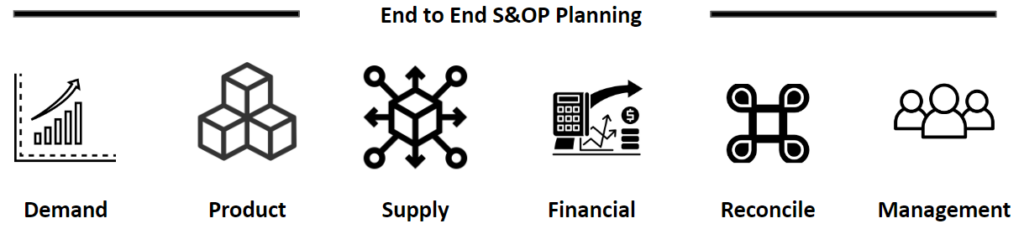

In a world where market conditions can change overnight, businesses must be prepared to navigate uncertainty. This is where scenario planning becomes a crucial component of the Sales and Operations Planning (S&OP) process. Scenario planning allows organizations to model different potential futures and develop strategies to respond effectively to unexpected events. By incorporating scenario planning into S&OP, companies can make more informed decisions, minimize risks, and seize opportunities in a dynamic market environment.

Building Scenarios: Modeling Demand Fluctuations and Supply Chain Disruptions

The first step in scenario planning is to build a range of possible scenarios that reflect various market conditions and uncertainties. These scenarios should encompass both demand fluctuations and supply chain disruptions to provide a comprehensive view of potential challenges.

1. Modeling Demand Fluctuations

Demand can be highly unpredictable, influenced by factors such as changing customer preferences, economic conditions, competitor actions, and market trends. To model demand fluctuations, organizations should:

- Identify Key Variables: Start by identifying the key variables that impact demand, such as sales growth rates, customer segments, seasonal trends, and promotional activities.

- Develop Multiple Scenarios: Create multiple demand scenarios that capture a range of possibilities. For example, develop a “best-case” scenario with high demand growth, a “worst-case” scenario with a significant demand decline, and a “moderate” scenario that represents stable demand.

- Use Historical Data and Predictive Analytics: Leverage historical sales data, market research, and predictive analytics tools to model these scenarios accurately. This approach helps anticipate how demand might change under different conditions.

2. Modeling Supply Chain Disruptions

Supply chain disruptions, such as supplier delays, transportation bottlenecks, geopolitical risks, and natural disasters, can significantly impact a company’s ability to meet demand. To model supply chain disruptions, consider:

- Identify Potential Disruption Points: Map out the entire supply chain and identify potential points of failure, such as critical suppliers, transportation hubs, or manufacturing facilities.

- Develop Disruption Scenarios: Create scenarios that capture different types of supply chain disruptions. For instance, consider scenarios where a key supplier faces a production halt, or a major port is temporarily closed due to a natural disaster.

- Assess Resilience: Evaluate the resilience of your supply chain under each scenario. This includes assessing alternative sourcing options, safety stock levels, and lead times to determine how quickly you can recover from disruptions.

By building comprehensive demand and supply chain scenarios, organizations can better understand the range of possible futures and be prepared for unexpected events.

Impact Analysis: Assessing Scenarios’ Effects on Operations and Informing Decision-Making

Once the scenarios are built, the next step is to conduct an impact analysis to understand how each scenario would affect the organization’s operations. This process involves evaluating the potential outcomes of each scenario and using this information to inform strategic decision-making.

1. Evaluating Operational Impact

Impact analysis begins with assessing how each scenario would impact different aspects of the business, such as inventory levels, production schedules, workforce requirements, and financial performance. For example:

- Inventory Management: Determine how inventory levels would be affected under different demand and supply scenarios. Would a sudden spike in demand deplete stock levels? Would a supply chain disruption create excess inventory?

- Production Planning: Assess how production schedules would need to be adjusted to respond to each scenario. Can production be ramped up or scaled down quickly? Are there bottlenecks that could hinder flexibility?

- Financial Implications: Analyze the financial impact of each scenario, including changes in revenue, costs, and profitability. For instance, a demand surge may require additional investment in production capacity, while a supply chain disruption could increase costs due to expedited shipping or alternative sourcing.

2. Informing Decision-Making

The insights gained from impact analysis can be used to inform strategic decisions and prepare for potential challenges. Here’s how scenario planning can drive better decision-making:

- Develop Contingency Plans: Use the results of the impact analysis to create contingency plans for each scenario. For example, if a key supplier faces a disruption, a contingency plan might include identifying alternative suppliers or increasing safety stock levels.

- Enhance Agility: Scenario planning enables organizations to be more agile by anticipating potential challenges and having predefined responses ready. This agility is crucial for quickly adapting to changes in demand or supply conditions.

- Prioritize Investments: Assess which investments are most critical based on the likelihood and impact of each scenario. For example, investing in advanced analytics tools or diversifying the supplier base might be prioritized if these actions mitigate risks across multiple scenarios.

- Strengthen Cross-Functional Alignment: Share scenario planning insights across departments to ensure alignment and coordinated responses. Regular communication between sales, operations, finance, and supply chain teams ensures that everyone is prepared for the same set of potential futures.

Conclusion

Scenario planning is an essential tool in today’s uncertain business environment. By building scenarios that model demand fluctuations and supply chain disruptions, and conducting thorough impact analysis, organizations can better prepare for the unexpected. Integrating scenario planning into the S&OP process helps companies make informed decisions, reduce risks, and capitalize on opportunities, ultimately enhancing their ability to thrive in a dynamic market landscape.

Explore More on S&OP Best Practices

- S&OP Process: A Comprehensive Guide – Dive into a detailed guide on building an effective S&OP process from start to finish.

- Integrating S&OP with Financial Planning: Aligning Goals – Understand the importance of aligning S&OP with financial planning to drive business success.

- Enhancing S&OP with CPFR: Collaborate for Better Outcomes – Explore how Collaborative Planning, Forecasting, and Replenishment (CPFR) enhances S&OP through supplier and customer collaboration.

- S&OP Maturity Models: Assess and Advance Your Process – Discover how to evaluate and enhance your S&OP process using maturity models.

- Scenario Planning in S&OP: Preparing for Market Uncertainties – Learn how scenario planning helps businesses anticipate market changes and manage risks.

- Change Management and S&OP: Implementing and Sustaining Success – Find out how to effectively implement and maintain S&OP through strategic change management.

- Choosing the Right Software Solution for Your S&OP Process – Evaluate the alternatives and make the best choice possible for your organization

- Custom build your S&OP Process with Microsoft Fabric – Instead of using a third party tool, custom build your S&OP process with a data pipeline