Enhancing S&OP with CPFR

Enhancing S&OP with Collaborative Planning, Forecasting, and Replenishment (CPFR)

Successful businesses know that collaboration is the key to staying ahead. While traditional Sales and Operations Planning (S&OP) focuses on aligning internal departments to optimize supply and demand, integrating Collaborative Planning, Forecasting, and Replenishment (CPFR) can take this alignment to the next level. CPFR is a powerful strategy that enhances S&OP by fostering closer collaboration with both suppliers and customers, ensuring synchronized planning through shared information.

CPFR Overview: Synchronized Planning Through Shared Information

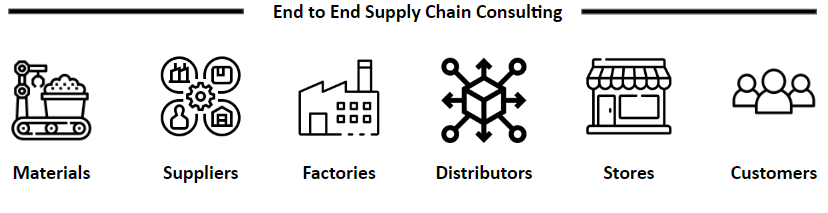

Collaborative Planning, Forecasting, and Replenishment (CPFR) is a business practice where trading partners, such as suppliers, manufacturers, and retailers, work together to improve supply chain efficiency. Unlike traditional planning processes that often occur in silos, CPFR involves sharing real-time data, insights, and forecasts among partners to create a more accurate and unified plan.

This synchronized approach enables all parties to better anticipate demand, align production schedules, and manage inventory levels. It reduces uncertainty and fosters trust by creating a transparent environment where information flows freely. For example, if a retailer shares their sales data with a manufacturer, both can work together to ensure that products are available when needed, reducing the risk of stockouts or overstocking.

By integrating CPFR into S&OP, businesses can bridge the gap between internal planning and external collaboration, leading to more effective decision-making and greater overall efficiency.

Benefits of CPFR: Improved Visibility, Inventory Optimization, and Stronger Collaboration

Adopting CPFR offers several key benefits that can significantly enhance the S&OP process:

1. Improved Visibility Across the Supply Chain

One of the most significant advantages of CPFR is the enhanced visibility it provides across the entire supply chain. When trading partners share data, it creates a single source of truth that everyone can rely on. This shared visibility allows all parties to better understand demand patterns, market trends, and potential disruptions.

With this information, businesses can make more informed decisions, reduce uncertainty, and quickly respond to changes in the market. For example, if a supplier knows about a spike in demand from a retailer, they can ramp up production in advance to meet that demand, avoiding delays and maintaining customer satisfaction.

2. Inventory Optimization and Cost Savings

CPFR helps optimize inventory levels by enabling more accurate demand forecasting and production planning. When partners work together to forecast demand and plan replenishment schedules, they can reduce the risk of both stockouts and excess inventory.

This optimization leads to significant cost savings. With fewer stockouts, businesses can avoid lost sales and maintain higher customer satisfaction levels. On the other hand, reducing excess inventory lowers holding costs, minimizes waste, and improves cash flow. For instance, a manufacturer can adjust its production runs based on real-time sales data from retailers, reducing the need to maintain large safety stocks and cutting down on storage costs.

3. Stronger Supplier-Customer Collaboration

CPFR fosters stronger relationships between suppliers and customers by promoting a collaborative approach to planning and forecasting. This collaboration builds trust and transparency, as both parties work towards common goals and benefit from each other’s insights and expertise.

A strong supplier-customer partnership can lead to several positive outcomes, such as improved negotiation terms, more flexible agreements, and better risk management. When suppliers and customers share information and work together, they can quickly address potential issues, such as delays or supply shortages, and develop mutually beneficial solutions.

For example, if a retailer shares promotional plans with a supplier, the supplier can prepare in advance to meet the expected surge in demand, ensuring that products are available when needed. This proactive approach benefits both parties: the retailer can capitalize on the promotion without worrying about stockouts, while the supplier gains a more predictable demand forecast.

How to Implement CPFR for Enhanced S&OP

Implementing CPFR effectively requires a strategic approach that focuses on collaboration, communication, and technology:

- Establish Clear Communication Channels: Open and frequent communication is critical for successful CPFR. Set up regular meetings, share forecasts, and ensure that all parties have access to real-time data.

- Leverage Integrated Technology Tools: Use integrated software tools that allow for real-time data sharing and analysis. Tools that support data integration across multiple partners help eliminate silos and enhance collaboration.

- Define Shared Goals and KPIs: Clearly define shared goals, such as inventory turnover rates or order fill rates, to align all partners towards common objectives. Establish key performance indicators (KPIs) that all parties can use to measure progress and make adjustments as needed.

- Develop Joint Action Plans: Create joint action plans that outline roles, responsibilities, and processes for collaboration. Ensure that all partners are aware of their contributions to the CPFR process and understand how they will benefit from it.

There are a number of good software solutions to enable the collaboration process. For a BlueYonder ecosystem, their S&OP solution is a good tool for managing the process. In other cases, companies can implement a tool themselves through platforms like Snowflake and Databricks.

Conclusion

Integrating Collaborative Planning, Forecasting, and Replenishment (CPFR) into your S&OP process offers a powerful way to enhance supply chain efficiency, reduce costs, and improve customer satisfaction. By fostering collaboration with suppliers and customers through shared information and synchronized planning, businesses can gain greater visibility, optimize inventory, and build stronger partnerships. Start leveraging CPFR today to transform your S&OP process and drive sustainable growth.

Explore More on S&OP Best Practices

- S&OP Process: A Comprehensive Guide – Dive into a detailed guide on building an effective S&OP process from start to finish.

- Integrating S&OP with Financial Planning: Aligning Goals – Understand the importance of aligning S&OP with financial planning to drive business success.

- Enhancing S&OP with CPFR: Collaborate for Better Outcomes – Explore how Collaborative Planning, Forecasting, and Replenishment (CPFR) enhances S&OP through supplier and customer collaboration.

- S&OP Maturity Models: Assess and Advance Your Process – Discover how to evaluate and enhance your S&OP process using maturity models.

- Scenario Planning in S&OP: Preparing for Market Uncertainties – Learn how scenario planning helps businesses anticipate market changes and manage risks.

- Change Management and S&OP: Implementing and Sustaining Success – Find out how to effectively implement and maintain S&OP through strategic change management.

- Choosing the Right Software Solution for Your S&OP Process – Evaluate the alternatives and make the best choice possible for your organization

- Custom build your S&OP Process with Microsoft Fabric – Instead of using a third party tool, custom build your S&OP process with a data pipeline