Effective Steps in the S&OP Process for your Supply Chain

Sales and Operational Planning (S&OP) is a vital process for organizations seeking to align their business activities with their strategic objectives and optimize resource allocation. It’s a recurring monthly procedure, starting from the last week of a month and concluding by the fourth week of the following month, encompassing five weeks. In this article, we will provide an high level overview of the end-to-end global S&OP process, breaking it down into its constituent sub-processes. This process is crucial for maintaining the supply and demand equilibrium and ensuring that an organization’s operations are aligned with its financial goals.

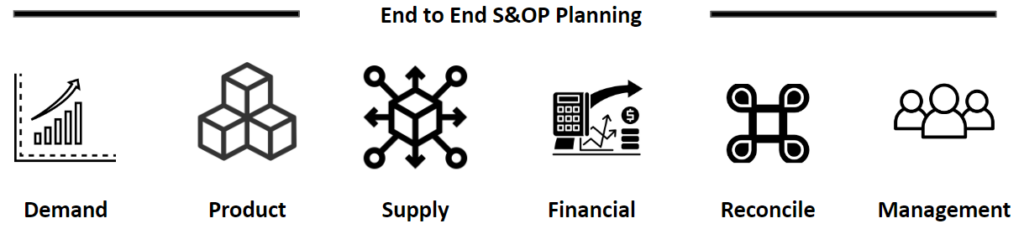

Sub-Processes in End-to-End Global S&OP

- Demand Review: The S&OP process starts with the Demand Review. This stage encourages cross-functional collaboration, particularly between sales, marketing, and relevant departments, to formulate a demand plan or forecast. The Demand Review includes:

- Collecting market and dealer inputs.

- Reviewing regional demand plans.

- Reviewing global demand plans.

- Product Review: Following the Demand Review is the Product Review. This step oversees new product introductions and phase-outs by evaluating project plans. Product Review ensures that phase-in and phase-out dates are in harmony with the strategic goals, including the annual operating plan. Any adjustments in forecasts are made in conjunction with demand review and product management.

- Supply Review: Supply Review is the next step in the S&OP process. This phase harnesses the output of the Demand Review and tasks the supply planning team with the objective of satisfying the demand plan (forecasts) within a reasonable cost and without violating constraints. Key business functions, including manufacturing, engineering, quality, purchasing, planning, and final assembly, are involved. The monthly Supply Review encompasses:

- Evaluating actual performance against the agreed supply plan.

- Reviewing demand-supply alignment and making necessary adjustments.

- Financial Review: The Financial Review happens at each sub-process stage in the Integrated Business Management process. Finance takes a close look at the supply and demand plans from a financial perspective, including budgets, annual operating plans, margin, and price plans. Finance works with supply and demand teams to address any financial issues during a pre-S&OP meeting review. This review ensures that the plans align with the organization’s financial objectives.

- Integrated Reconciliation: Integrated Reconciliation is a crucial stage where any imbalances between supply and demand plans are addressed. Various alternatives to mitigate these imbalances are evaluated, and a consensus is reached between the supply and demand plans. This stage results in:

- A review of demand/supply imbalances and discussion of options to resolve them.

- Preparation of an issues list for the Management Business Review process.

- A review of gaps between the budget and the last plan.

- Management Review: The final stage in the S&OP process is the Management Business Review meeting or Executive meeting. In this meeting, all the previous steps (processes) are consolidated into a formal presentation for top management. Top management reviews the enterprise plan and evaluates its alignment with strategic objectives and business plans. Outstanding issues are addressed, and a final consensus plan is developed. This consensus plan guides the activities of various functions.

- Monitor, Measure, and Revise: The S&OP process doesn’t end with the Management Review. It involves an ongoing and continuous process step for monitoring and adherence. Once the monthly plan is established, it must be tracked on a weekly basis. If deviations from the original plan occur, this step allows for revising the plan to address these deviations.

Conclusion

The end-to-end global S&OP process is a meticulously structured approach to ensuring that an organization’s supply and demand are in harmony with its financial goals and strategic objectives. By breaking down the S&OP process into these sub-processes, organizations can achieve greater control and transparency in their operations, leading to more effective business planning and decision-making. Continuous monitoring and revision further enhance the adaptability and agility of an organization in a dynamic business environment.

Here are the other supply chain processes we support including demand planning, master planning, and fulfillment provided by our partners like BlueYonder, o9, and Kinaxis.

Explore More on S&OP Best Practices

- S&OP Process: A Comprehensive Guide – Dive into a detailed guide on building an effective S&OP process from start to finish.

- Integrating S&OP with Financial Planning: Aligning Goals – Understand the importance of aligning S&OP with financial planning to drive business success.

- Enhancing S&OP with CPFR: Collaborate for Better Outcomes – Explore how Collaborative Planning, Forecasting, and Replenishment (CPFR) enhances S&OP through supplier and customer collaboration.

- S&OP Maturity Models: Assess and Advance Your Process – Discover how to evaluate and enhance your S&OP process using maturity models.

- Scenario Planning in S&OP: Preparing for Market Uncertainties – Learn how scenario planning helps businesses anticipate market changes and manage risks.

- Change Management and S&OP: Implementing and Sustaining Success – Find out how to effectively implement and maintain S&OP through strategic change management.

- Choosing the Right Software Solution for Your S&OP Process – Evaluate the alternatives and make the best choice possible for your organization