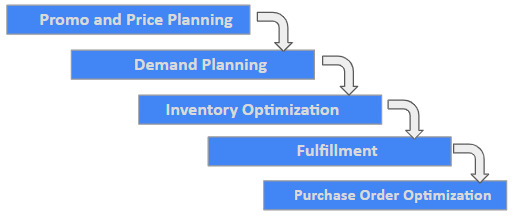

The Natural Progression of Planning Operations

In the complex world of supply chain management, well-orchestrated planning operations are the cornerstone of success. In a simplistic form, the journey begins with the intricate dance of Promo and Price Planning and culminates in the seamless execution of Purchase Order Optimization. Let’s explore this natural progression of planning operations and uncover the art and science behind each step:

1. Promo and Price Planning

At the outset of supply chain planning, we encounter Promo and Price Planning. This is where the big impact on demand is orchestrated, often in conjunction with external systems like Revionics or DemandTec, or within the ambit of solutions like Blue Yonder. Here, the aim is to strategically plan promotions and pricing strategies that drive demand. It’s a realm of unconstrained possibilities, where creativity and market insight come into play to entice customers.

2. Demand Planning

The next step in the planning journey is Demand Planning. It’s here that the base demand is meticulously calculated, taking into account factors such as base prices, historical data, events, and more. Demand Planning separates base demand from promotional demand, providing a clearer picture of what to expect in terms of customer requirements.

3. Inventory Optimization

With demand understood, the spotlight shifts to Inventory Optimization. In this phase, the goal is to ensure that unconstrained inventory levels are optimized to meet both regular demand and the surge in demand triggered by promotions. Inventory Optimization is a delicate balancing act, ensuring that stock levels are neither excessive nor insufficient to fulfill customer needs.

4. Fulfillment and Replenishment

Fulfillment marks the transition from unconstrained operations to a more constrained environment. Here, mathematical precision comes into play as the system calculates the net orders against the actual inventory on hand. Fulfillment ensures that products are allocated efficiently to meet customer demands while optimizing the utilization of available stock.

5. Purchase Order Optimization

As the final piece of the puzzle, Purchase Order Optimization is where order assignment takes place. It’s about determining which orders are assigned to which fulfillment centers or suppliers, all while considering various constraints and factors such as cost, delivery times, and customer preferences.

This waterfall model is the clearest path through planning. More complex organizations or different industries may require specializations in Master Planning, Sales and Operations Planning, or Customer Order Promising.

The Art vs. Science in Planning

In the planning process, two distinct realms exist—the “art” and the “science.” Promo and Price Planning, as well as Demand Planning, require a more creative and interactive approach. These phases involve what-if scenarios, market insights, and the art of understanding customer behavior.

On the other hand, Fulfillment and Order Optimization lean more towards the “science” side. They involve technical precision, adherence to business rules, and execution based on real data.

The Key to Success: Integration and Continual Refinement

The success of this natural progression lies in seamless integration between these planning operations. Each step informs the next, creating a synchronized flow of information and decision-making. Moreover, supply chain planning is not a one-time endeavor; it’s an ongoing journey of refinement and optimization. As market dynamics change and customer preferences evolve, the planning process must adapt to stay competitive.

Supply chain planning is a multifaceted journey that requires both artistry and scientific precision. By addressing each step in the natural progression of planning operations and embracing the integration of these steps, K3 can help you unlock the key to supply chain excellence, ensuring you meet customer demands efficiently and effectively in an ever-changing market landscape.